Introduction

In the medical device industry, selecting the right raw materials is crucial—not only for product performance but, more importantly, for patient safety. Over the years, medical-grade PVC (polyvinyl chloride) has emerged as one of the most trusted materials for manufacturing disposable medical devices.

Renowned for its chemical stability, flexibility, transparency, and biocompatibility, medical-grade PVC is the preferred choice for critical applications such as suction tubes, IV sets, catheters, and blood bags. Its unique properties ensure reliability, ease of use, and compliance with stringent medical standards.

At Makhazen Tabi Abadis, we specialize in leveraging medical-grade PVC’s advantages to produce high-quality suction tubes and other essential medical consumables. In this article, we explore:

- Why medical-grade PVC stands out among other materials

- Key industry standards ensuring safety and performance

- Real-world applications, particularly in suction tube manufacturing

By understanding the science and benefits behind this material, healthcare providers and manufacturers can make informed decisions—enhancing both patient care and operational efficiency.

What Is Medical-Grade PVC?

Medical-grade PVC is a specially formulated version of polyvinyl chloride designed to meet the stringent health, safety, and performance standards required in medical and pharmaceutical applications. While it is derived from vinyl chloride monomers like conventional PVC, medical-grade variants are free from harmful plasticizers like DEHP and often incorporate biocompatible alternatives such as TOTM or DINCH.

Key Properties:

- Biocompatibility: Safe for direct contact with tissues, fluids, and airways.

- Flexibility: Adjustable softness makes it ideal for tubes used in narrow or delicate anatomical pathways.

- Transparency: Allows real-time monitoring of fluid flow through the tube.

- Sterilizability: Compatible with EO gas, gamma radiation, and autoclaving.

- Chemical Resistance: Withstands exposure to disinfectants and pharmaceutical agents.

- Non-toxicity: Free of allergens like latex and harmful additives.

These features distinguish medical-grade PVC from standard industrial PVC, positioning it as an ideal material for safe, high-performance, and mass-produced medical devices.

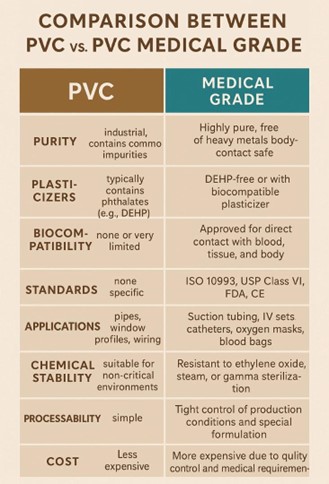

A comparison table highlights the key differences between regular PVC and medical-grade PVC. As shown, medical-grade PVC features higher purity, biocompatibility suitable for human contact, and is free from harmful chemicals like DEHP. It also complies with international standards such as ISO 10993 and FDA regulations.

These properties make it the ideal choice for manufacturing medical devices, including suction tubes, IV sets, and blood bags.

Certifications and International Standards

Reputable manufacturers of medical-grade PVC comply with internationally recognized standards, including:

- ISO 10993 – Biological evaluation of medical devices

- USP Class VI – U.S. Pharmacopeia standards for biocompatibility

- FDA 21 CFR Part 820 – U.S. Food & Drug Administration’s Quality System Regulation

- European Pharmacopoeia (EP) – For materials used in contact with medications or blood

Compliance with these standards guarantees that PVC is non-cytotoxic, non-irritant, and non-sensitizing, making it a medically sound option for patient care.

Why Medical-Grade PVC is Ideal for Suction Tubes

In modern healthcare, suction tubes serve as vital tools for maintaining patient airways and managing bodily fluids during medical procedures. These devices require materials that combine safety, functionality, and reliability – qualities that medical-grade PVC delivers exceptionally well.

The inherent flexibility of PVC allows suction tubes to navigate delicate anatomical structures with minimal patient discomfort, while its crystal-clear transparency enables healthcare providers to monitor fluid removal in real-time. What truly sets medical-grade PVC apart is its rigorous compliance with international safety standards, including ISO 10993 and FDA regulations, ensuring complete biocompatibility for prolonged patient contact.

Beyond its clinical advantages, PVC demonstrates remarkable resistance to chemicals and sterilization methods, maintaining its structural integrity whether autoclaved, exposed to ethylene oxide, or treated with gamma irradiation. This durability, combined with cost-effective manufacturing potential, makes PVC the pragmatic choice for healthcare institutions worldwide.

At Makhazen Tabi Abadis, we harness these superior material properties to engineer suction tubes that meet the highest standards of medical care. The widespread adoption of PVC by leading global manufacturers stands as testament to its unmatched performance in critical healthcare applications, where patient safety and clinical effectiveness remain paramount.

By selecting PVC-based medical devices, healthcare providers invest in solutions that combine scientific innovation with practical reliability – ensuring optimal patient outcomes while maintaining operational efficiency in demanding clinical environments.

Why Top Medical Brands Choose medical-grade PVC for Critical Healthcare Products

Across the global healthcare industry, medical-grade PVC has become the material of choice for manufacturers producing life-saving devices. Some of the world’s most trusted medical companies rely on PVC’s unique properties for their essential products:

- Terumo (Japan) uses medical PVC in their precision blood collection systems and infusion sets

- Tekni-Plex Healthcare (USA) develops specialized PVC formulations for sterilization-resistant tubing

- Manner Polymers (USA) creates custom PVC solutions for respiratory therapy equipment

- Xenco Medical (USA) incorporates medical-grade polymers in single-use surgical tools

- Henso Medical (China) exports PVC-based suction catheters and disposables worldwide

These industry leaders – and hundreds more – select medical-grade PVC because it delivers what matters most in healthcare: consistent quality, patient safety, and manufacturing reliability. At our company, we’re proud to work with this same high-standard material, ensuring our medical devices meet the rigorous demands of modern healthcare alongside these global manufacturers. The widespread adoption of PVC by top-tier medical brands speaks volumes about its unmatched value in creating safe, effective healthcare solutions.

Iran’s Growing Medical PVC Industry

Iran’s medical sector is embracing medical-grade PVC to meet rising demand for internationally compliant devices. Leading this change are:

- Pharmed Plast – Produces IV sets and breathing tubes using certified PVC materials

- Granol Mahsoul – Supplies high-quality PVC materials to local manufacturers

This shift shows how Iran is:

✔ Improving medical product quality

✔ Reducing reliance on imports

✔ Building stronger healthcare infrastructure

By using medical-grade PVC, these companies prove that local production can meet international standards while supporting Iran’s medical self-sufficiency.

Why We Trust Medical-Grade PVC for Our Suction Tubes

At Makhazen Tabi Abadis, every material decision comes down to three non-negotiables: patient safety, clinical effectiveness, and manufacturing excellence. That’s why we’ve selected medical-grade PVC as the foundation of our suction tube production. Here’s what makes it the smart choice:

- Patient-First Design

- Ultra-soft flexibility that minimizes discomfort during procedures

- Crystal-clear tubing for real-time fluid monitoring

- Rigorously tested biocompatibility (ISO 10993 compliant)

- Hospital-Ready Performance

- Withstands all standard sterilization methods

- Maintains integrity under clinical use

- Seamlessly connects to medical equipment

- Smart Manufacturing Benefits

- Consistent quality for reliable mass production

- Cost-efficient without compromising safety

- Meets both regional and international standards (CE/ISO)

We don’t just make tubes – we engineer clinical solutions. By combining medical-grade PVC with precision manufacturing, we’re able to deliver:

✓ Affordable healthcare products

✓ Export-quality reliability

✓ Trusted performance in critical care situations

For us, material selection isn’t just a technical decision – it’s a commitment to better patient outcomes across the region.

Final Conclusion: Why Medical-Grade PVC is the Future of Medical Device Manufacturing

After carefully examining the technical, biological, and functional properties of medical-grade PVC, one thing becomes clear: this material stands as one of the best choices for producing disposable medical equipment—especially suction tubes.

What Makes Medical-Grade PVC Unmatched?

✔ Adjustable flexibility for patient comfort and ease of use

✔ Certified biocompatibility ensuring patient safety

✔ High resistance to all sterilization methods (gamma, autoclave, EO gas)

✔ Exceptional transparency for real-time fluid monitoring

These properties don’t just benefit patients—they also offer major advantages for manufacturers:

- Superior processability in extrusion and injection molding production lines

- Compatibility with non-DEHP plasticizers (like TOTM) for enhanced safety

- Lower production costs compared to alternatives like silicone or polyurethane

Global Trust in Medical-Grade PVC

Leading international manufacturers—including Terumo (Japan), Tekni-Plex (USA), Henso Medical (China), and Xenco Medical (USA)—rely on medical-grade PVC for advanced medical devices. This widespread adoption confirms its credibility among healthcare professionals worldwide.

Makhazen Tabi Abadis: Committed to Quality & Safety

At Makhazen Tabi Abadis, we incorporate medical-grade PVC in our single-use suction tubes, adhering to international standards and cutting-edge technology. Our choice is backed by:

- Scientific research

- Real-world clinical experience

- Strict safety and hygiene protocols

The Future of Medical Devices Relies on Smart Material Choices

The growing demand for high-quality, safe medical equipment—especially post-pandemic—has highlighted the critical role of standardized raw materials. Medical-grade PVC has solidified its position as a strategic material in the medical device industry, perfectly balancing performance, safety, and cost-efficiency.

Looking ahead, the future of medical manufacturing—particularly in respiratory equipment, catheters, suction tubes, and fluid transfer systems—will be closely tied to the intelligent use of advanced materials like medical-grade PVC.

At Makhazen Tabi Abadis, we’re proud to be part of this evolution, delivering reliable, high-performance medical solutions that meet global standards while supporting healthcare providers and patients alike.

References

[1] RAUMEDIC, “The important role of PVC in medical devices and applications,” [Online]. Available: https://www.raumedic.com/us/insights/the-important-role-of-pvc-in-medical-devices-and-applications. [Accessed: May 28, 2025].

[2] European Council of Vinyl Manufacturers (ECVM), “PVC in healthcare,” [Online]. Available: https://pvc.org/pvc-applications/pvc-in-healthcare/. [Accessed: May 28, 2025].

[3] Kent Elastomer, “Medical grade PVC tubing benefits and uses,” [Online]. Available: https://www.kentelastomer.com/pvc-benefits-uses/. [Accessed: May 28, 2025].

[4] INEOS Compounds, “PVC medical products,” [Online]. Available: https://www.ineos.com/businesses/ineos-enterprises/businesses/ineos-compounds/markets/pvc-medical-products/. [Accessed: May 28, 2025].

[5] M. Ionescu et al., “Selecting medical grade polymers and testing for achieving antibacterial devices tubular prosthetic,” ResearchGate, 2013.

[6] J. Smith et al., “Surface modification of polyvinylchloride for manufacturing advanced catheters,” ResearchGate, 2020.