Introduction

The medical device industry is one of the most critical sectors worldwide, as even the slightest error in design or production can lead to irreversible consequences for patient health. Among the widely used tools in this industry, the

suction tube holds a special place.

This seemingly simple yet highly practical device plays a crucial role in evacuating secretions, blood, and bodily fluids during surgery, intensive care, and emergency departments. Using a standardized suction tube can directly enhance surgical efficiency and patient safety while preventing complications such as airway obstruction and contamination of the surgical environment.

Suction tubes are usually made from medical-grade plastics and packaged sterile. Due to direct contact with patients’ bodies and vital fluids, the quality and safety of this device are paramount. Manufacturers must adhere to a set of international and national standards throughout all stages—from design and material selection to sterilization and packaging.

This article reviews the most important standards for producing medical suction tubes and explains why compliance is essential for manufacturers and healthcare providers.

The Importance of Compliance with Standards in Suction Tube Production

1. Ensuring Patient Safety:

Using standardized suction tubes reduces the risk of infections and cross-contamination. Non-standard tubes can cause allergic reactions, cross-infections, or even transmit pathogens.

2. Enhancing Product Quality:

Standards ensure that tubes are resistant to tearing, kinking, and obstruction. Flexibility and durability are guaranteed under various clinical conditions, directly supporting medical team performance.

3. Compliance with Global Regulations:

Producing according to international standards such as ISO and CE facilitates export and access to foreign markets, boosting company revenue and establishing brand credibility worldwide.

4. Building Trust with Healthcare Professionals:

Hospitals and physicians prefer standardized medical equipment. Compliance increases trust in your brand, encouraging repeat and long-term purchases.

5. Reducing Legal and Financial Risks:

Non-compliance can result in heavy fines, product recalls, or legal action. Adhering to standards ensures compliance with national and international laws.

Overall, following standards allows suction tubes to meet domestic demand and succeed in international markets.

International Standards for Suction Tube Production

Producing medical suction tubes requires compliance with international standards that ensure quality, safety, and performance. The key standards include:

1. ISO 13485 – Quality Management System

ISO 13485 is one of the most widely used standards in medical devices and focuses on quality management. It emphasizes that all production processes, from design to delivery, must be documented, traceable, and under strict quality control.

Key points:

•Design and production must be documented and traceable.

•Quality control applied at all stages, from raw materials to packaging.

•Raw materials must meet safety and biocompatibility requirements.

•Detailed documentation of production processes and quality tests ensures quick traceability and correction of issues.

2. ISO 10993 – Biological Evaluation

Since

suction tubes come into direct contact with the patient’s body and fluids, they must be made of materials that do not cause allergic reactions, toxicity, or carcinogenic effects.

Key points:

•Cytotoxicity: The product should not cause cell death.

•Skin and tissue irritation: Contact with patient tissue must be safe.

•Systemic toxicity testing: Tubes must not harm internal organs or body systems.

3. ISO 14971 – Risk Management

Manufacturers must identify and manage potential risks associated with suction tube use, minimizing medical and operational hazards.

Common risks addressed:

•Tube rupture or blockage disrupting fluid flow.

•Cross-contamination increasing infection risk.

•Tissue damage due to improper use or substandard materials.

4. ISO 11135 & ISO 11137 – Sterilization Processes

Suction tubes are typically supplied sterile.

•ISO 11135: Sterilization using ethylene oxide.

•ISO 11137: Sterilization using gamma radiation.

These standards ensure that products are ready for use in operating rooms without additional sterilization.

5. CE Marking (European Union)

Suction tubes sold in Europe must carry the CE mark, confirming compliance with EU safety, performance, and biocompatibility requirements.

•CE marking increases trust among European healthcare providers.

•Without it, legal sales in the EU market are not possible.

6. FDA (U.S. Food and Drug Administration)

For export to the U.S., manufacturers must comply with FDA 21 CFR Part 820, which covers:

•Product quality control

•Documentation of production processes

•Medical device traceability

Compliance ensures that suction tubes are legal and recognized in the U.S. market.

Expected Quality Features of Standard Suction Tubes

To ensure optimal performance, a medical suction tube must meet technical and quality criteria beyond international standards:

1. High-Quality Raw Materials:

•Typically made from medical-grade PVC or silicone.

•Materials must be non-toxic, flexible, and tear-resistant.

2. Appropriate Flexibility:

•Allows easy navigation in complex body pathways.

•Prevents tissue damage or fluid flow obstruction.

3. Transparency:

•Tubes are often transparent or semi-transparent for fluid monitoring.

•Enables precise control and rapid response in emergencies.

4. Resistance to Kinking and Tearing:

•Tubes must withstand bending in complex surgical or ICU conditions.

5. Variety of Sizes:

•Produced in sizes 25 to 35 to suit surgery type, patient age/weight, and location.

6. Compatibility with Accessories:

•Must fit suction connectors, filters, and other hospital equipment.

7. Packaging and Sterilization:

•Packaging prevents contamination and maintains sterilization.

•Typically sterilized with ethylene oxide or gamma radiation.

National Standards in Iran

In Iran, medical device production, including suction tubes, is regulated by the Institute of Standards & Industrial Research of Iran (ISIRI) and the Ministry of Health and Medical Education. Compliance ensures patient safety, allows domestic marketing, and prepares products for export.

Key requirements:

1.Production license from IMED: Official authorization for producing disposable medical devices.

2.Compliance with international standards: Iranian manufacturers must follow ISO 13485, ISO 10993, and CE.

3.Strict quality control: All stages, from raw materials to packaging, undergo rigorous testing.

4.Verification of sterilization and biocompatibility: Products must be safe for human use.

Key Requirements of Iran National Standard No. 15504 for the Production of Medical Suction Tubes

Iran National Standard No. 15504, entitled “Single-use medical device – Suction tube for medical use – Characteristics and test methods”, is considered one of the most important technical references for the production and evaluation of medical suction tubes in Iran. This standard precisely specifies the physical, dimensional, mechanical, sterilization, testing, and labeling requirements of the product.

1. Raw Material Requirements

According to Standard No. 15504:

-

The materials used in the manufacture of suction tubes shall be medical grade and free from any toxic substances, impurities, air bubbles, cracks, flash, or visible defects.

-

The internal and external surfaces of the tube shall be smooth and uniform to prevent contamination buildup and flow obstruction.

2. Structural Requirements of the Suction Tube

The suction tube structure consists of three main components:

-

Tube body

-

Connector

-

End-piece

The design of these components shall ensure that:

-

Connections between parts are secure and leak-free

-

No unintended separation occurs during use

-

Uniform suction flow performance is maintained

3. Dimensional and Size Specifications

Standard No. 15504 explicitly addresses the following dimensions:

-

Outer diameter of the tube

-

Overall length of the suction tube

-

Size classification based on the Charrière (CH) system

Different sizes (e.g., CH25, CH30, CH35) shall be manufactured in accordance with standard tables, and specified dimensional tolerances shall be strictly observed to ensure full compatibility with hospital suction equipment.

4. Collapse Resistance

One of the most important performance indicators specified in Iran National Standard No. 15504 is the resistance of the suction tube to collapse under negative pressure. The suction tube must maintain its geometric shape and consistent functional performance under real operating conditions, particularly when negative pressure is applied by a suction device.

According to this standard:

-

The suction tube shall not collapse, become obstructed, or experience performance degradation when subjected to a negative pressure of approximately –300 mmHg.

-

The collapse resistance test shall be carried out under controlled temperature conditions and in accordance with the standard test method.

-

Permanent deformation after the application of negative pressure is not permitted, and the tube must return to its original condition after completion of the test.

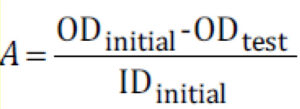

Degree of Flattening

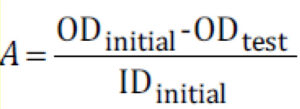

Within the same test, one of the key indicators used to evaluate the performance of the suction tube is the degree of flattening. The degree of flattening represents the extent of cross-sectional deformation of the tube under negative pressure and plays a direct role in maintaining a uniform suction flow.

According to the requirements of Standard 15504:

-

The degree of flattening of the suction tube along its entire length shall not exceed 0.5.

-

The degree of flattening is calculated based on the original dimensions of the tube and its deformed dimensions under negative pressure, and the calculated value must fall within the allowable limits specified by the standard.

-

Compliance with this requirement ensures that the suction tube does not suffer from flow reduction, blockage, or functional impairment during use.

The formula for calculating the degree of flattening is as follows:

5. Connector-to-Tube Joint Strength

According to the standard:

-

The joint between the connector and the tube body shall withstand a minimum tensile force of 50 N applied at a specified speed of 200 mm/min.

-

Separation or slippage of the joint during this test is not acceptable.

This requirement plays a vital role in preventing leakage, sudden suction disconnection, and enhancing patient safety.

6. Leakage Test

During the leakage test:

-

The suction tube shall be subjected to a specified air or water pressure.

-

No leakage, bubble formation, or air escape shall be observed.

This test ensures the operational safety of the tube under real clinical conditions.

7. Sterilization Requirements

According to Standard No. 15504:

Compliance with relevant reference sterilization standards for medical sterile devices is also mandatory.

8. Labeling and Packaging

Iran National Standard requires that the following information be clearly indicated on the packaging:

Packaging shall be designed to maintain product sterility until the point of use.

Challenges in Iran

- Access to high-quality medical-grade materials.

- High costs of obtaining international certifications.

- Need for modern sterilization and packaging equipment.

- Competition with foreign brands holding CE and FDA approvals.

Abadis Med Co is a leading Iranian manufacturer of disposable medical devices. By fully adhering to global standards such as ISO 13485 and ISO 10993, Abadis provides products suitable for both domestic and export markets.

Features of Abadis suction tubes:

•Made from medical-grade PVC

•Sterilized with ethylene oxide

•Transparent and durable design

•Produced in various sizes

•IMED-approved

Conclusion

Compliance with global standards in

suction tube production is non-negotiable. These standards ensure patient safety and enhance brand credibility in domestic and international markets.

Abadis Med Co, through modern technology and full compliance with ISO standards and Ministry of Health regulations, has secured a prominent position in disposable medical devices. Using Abadis standard suction tubes is a reliable way to reduce infection risks and improve healthcare quality.

References

1.ISO 13485:2016 – Medical devices — Quality management systems

https://www.iso.org/standard/59752.html

2.ISO 10993 – Biological evaluation of medical devices

https://www.iso.org/standard/68936.html

3.ISO 14971:2019 – Medical devices — Application of risk management

https://www.iso.org/standard/72704.html

4.ISO 11135 & ISO 11137 – Sterilization of medical devices

https://www.iso.org/

5.CE Marking for Medical Devices – European Commission

https://health.ec.europa.eu/medical-devices

6.FDA – U.S. Food & Drug Administration

https://www.fda.gov/medical-devices

7.Institute of Standards & Industrial Research of Iran – Medical Devices

https://www.isiri.gov.ir/

8.Iran Medical Equipment Directorate (IMED)

http://www.imed.ir/